Modularize to accelerate speed

to market and reduce costs

Our vertically integrated operation from engineering

to field provides seamless execution

Engineering, design and supply chain management are the bedrock of project excellence

Owners face mounting pressures to construct at a rapid pace in an ever-evolving environment that includes increasing customer demand, rising global competition and supply chain disruptions. Minimizing construction costs while ensuring high-quality infrastructure is essential for maximizing your return on investment. With the implications of labor, engineering/design, schedule, supply chain management & sustainability so tightly entwined, conventional delivery methods present challenges with management of multiple providers.

Overcoming these challenges requires centralized accountability across the value chain, fast-paced innovation, manufacturing best practices, high standards of safety, efficient maintenance planning and more.

LEARN MORE

Health, safety & environmental practices

HSE is more than guiding principles for our business decisions, it is at the heart of every thought and action. We aim to have a positive impact on our environment, the communities we work in and the people we employ through ensuring equal rights and operating in a sustainable way. Our team is engaged early and uses data for predictive analytics to reduce worksite incidents. Our goal of a zero-injury culture is supported by

strategy refinement

Engineering & design for manufacturing and assembly

Automating specific tasks in design and engineering is the root of efficiency for modularization projects. Through a consistent design, fabrication and construction teams can establish optimized processes which leverage consistency to produce repeatable outcomes at scale. With our engineering and design process, we drive repetition to a minimum threshold of 80% standardization. Our areas of expertise include:

Optimizing supply chain & logistics

We have an experienced and dedicated supply chain team that exclusively focuses on modular integration and data center projects. Our integrated process coordinates purchasing, inventory planning, production requirements along with managing engineering and specification changes throughout the project lifecycle. We maintain this level of agility and expedited delivery in tight collaboration with our highly valued partners. Further, we utilize:

Optimizing supply chain & logistics

We have an experienced and dedicated supply chain team that exclusively focuses on modular integration and data center projects. Our integrated process coordinates purchasing, inventory planning, production requirements along with managing engineering and specification changes throughout the project lifecycle. We maintain this level of agility and expedited delivery in tight collaboration with our highly valued partners. Further, we utilize:

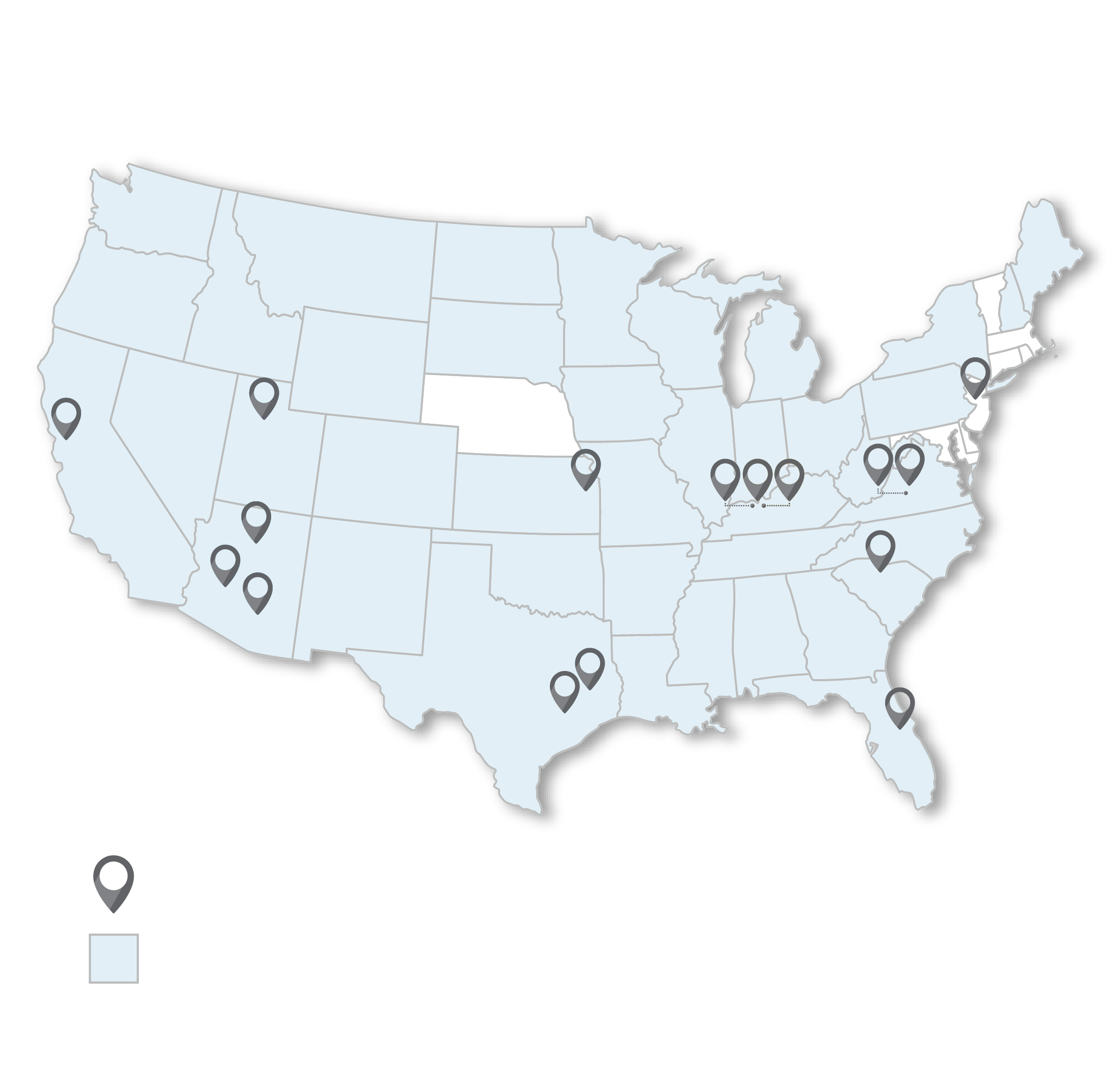

Unparalleled fabrication & integration capacity

Combining our 15 fabrication facilities and 2M+ square foot under roof with our network of national and international suppliers, we can manage programs of all sizes. Additionally, we source mod yard space when needed, based on the jobsite.

Our module delivery is supported by our integration team who works hand in hand with engineering to eliminate waste, optimize labor and install mechanical components to the modules with precision to ensure field install

Construction & field integration

We are builders at heart. Effective communication, coordination and adherence to project timelines are essential to successful in-field delivery. Leveraging the model and our building expertise, we set out safety plans, crane plans, installation scenarios and transportation routes.

Critical to success includes: